| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#41

|

||||

|

||||

|

I'm at the point of switching to a crank trigger and going away with the dual sync. Will be using the dual sync for cam only, would be nice if more people share specific info.

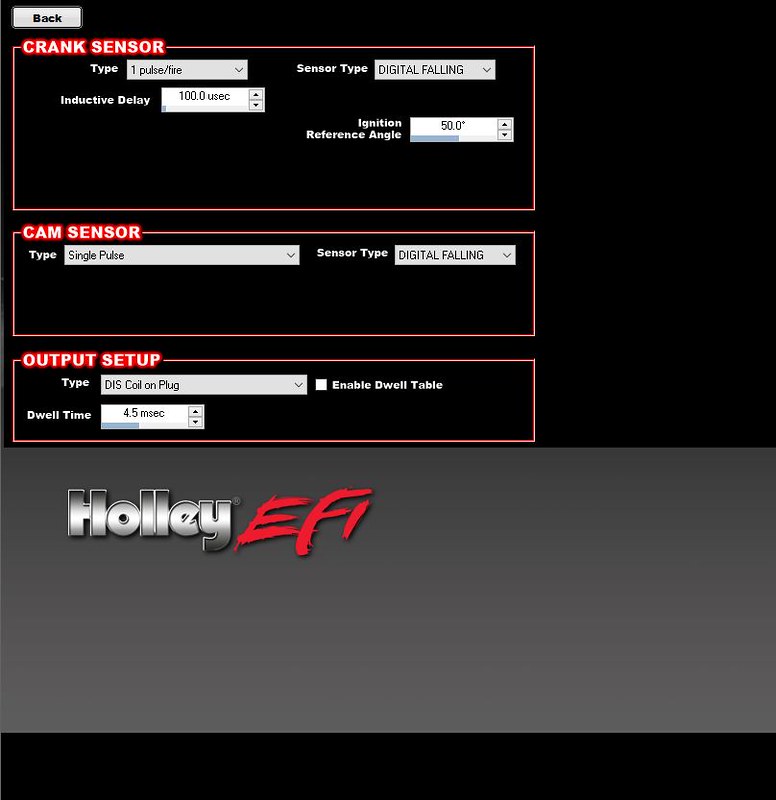

Couple references on the Holley forums that might be of help for some, figured I'd post since searching on that site is not very, um, fluid. Synchronizing timing: https://forums.holley.com/forum/holl...ng-Holley-EFI= Mag & Hall effect setup: https://forums.holley.com/forum/holl...-Sensor-Setup= LSx 24x setup info: https://forums.holley.com/forum/holl...ion=#post53735 Sample LSx 24 x 1 Cam setup using DIS: LSx 24x Crank & 1x Cam "Custom" Ignition Parameters: Ignition Type ....... - Custom Crank Sensor Type - LSx 24 Tooth Inductive Delay ... - 20.0 usec (← Adjust if necessary) Timing Offset ...... - 0° Cam Sensor Type . - Single Pulse (← Sequentially injected.) Sensor Type ........ - Digital Falling (← Sequentially injected.) Output Setup Type - DIS Coil on Plug Dwell Time .......... - 3.5-5.0 msec There's more info on that in the one thread link I posted. Timing Offset and Reference Angle are basically the same thing. You leave your dual sync as adjusted for the 50 degree ref angle if you've already sync'd your initial timing (and cut you plug wire lengths) and use a Timing Offset value of 50. I haven't tried this yet, but I'm going to. Different coils have different recommended dwell time values, one of those links have a link to the list. If you enter an incorrect dwell time value, it can impact timing. .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

| The Following User Says Thank You to HWYSTR455 For This Useful Post: | ||

|

#42

|

|||

|

|||

|

Just got off the dyno yesterday using the crank trigger setup shown in post #35 of this thread. The engine uses a Holley dual sync for the cam sensor. As we had problems with the dual sync crank signal on previous dyno runs, we switched to an external crank trigger using 4 magnets and a Hall effect sensor. The good news is that the new external crank trigger worked perfectly and solved all the problems we were having regarding crank signal.

However, the procedure to setup the dual sync part of the system (using the external crank trigger) is more complicated then you might expect. Here is a good video on how to do it properly, and this is the process we used with success on the dyno: https://www.youtube.com/watch?v=inQw...rmanceIgnition

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

| The Following 2 Users Say Thank You to darbikrash For This Useful Post: | ||

|

#43

|

||||

|

||||

|

Which Crank Sensor 'Type' selection did you use?

Here's the coil dwell info: "See the “Crank and Cam Sensor” setup in the Holley EFI help instructions on properly setting up the positions of the crank and cam sensors. The following is recommended Dwell times for various GM coil PN’s: Most coils can be set to a dwell time of 5.0 msec. Below are recommendations for various factory GM LS coils based upon Holley testing: The following coil should be set to a maximum of 5.0 msec: 10457730 The following coil should be set to a maximum of 4.5 msec. A Value greater than this may cause the coil to fire prematurely resulting in overly advanced ignition timing: 19005218 The following coils should be set to a maximum of 3.5 msec: 12573190 12611424 12570616 NOTE: If using the Holley® Smart Coils (P/N 556-112), please refer to the instruction sheet provided with them for recommended dwell times" .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#44

|

|||

|

|||

|

We experimented with coil dwell times between 4.0 msec and 5.0 msec. Didn't seem to make much difference so we set it at 4.5 msec and left it.

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#45

|

||||

|

||||

|

Great info in here!

Okay so upon reviewing my ignition parameters I think I need to do some work. My car runs great midrange and full throttle but is hard to start. It used to start okay on race gas but since switching the E85 its a pain. A few things I've noticed when looking at how mine is set up.

"Dwell Setting: - For street cars below 1.5 HP per cubic inch, the dwell should be set to 4.0 msec. - For cars that exceed 1.5 HP per cubic inch, the dwell should be set to 4.5 msec. - For high boost, maximum effort drag race engines, the dwell can be set to 5.0 msec." My engine is on E85 and is not a traditional "street" engine, but I do drive it on the street. Its got a ton of compression (13.8-1) and a healthy cam (272-283 .726" int .696" exh on 109LS). According to timeslip MPH I'm under the 1.5hp per cube mark though. I'm thinking the dwell time is fine for my application but wouldn't mind input on the subject.

__________________

James 1970 Trans Am Spotts Built 484" IA2, Highports, EFI Northwind Terminator X sequential EFI fabrication and suspension by https://www.funkhouserracecars.com/ |

|

#46

|

|||

|

|||

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#47

|

||||

|

||||

|

That sounds like really really high dwell. N/A I run 2 ms and run up to 3.5 ms over 3,500rpm. I wouldn't think you need over 4 ms unless you are pushing a lot of boost.

Coils will overheat with too much dwell time. Up until they overheat, there really isn't any downside to more dwell, except maybe more sparkplug electrode wear. Maybe I'm just overly cautious because some GM LS coils will "auto fire" over 4.5ms so I stay away from that number. And I'm sure Holley also does voltage compensation, so if your voltage drops on the top end it may add more dwell.

__________________

__________________________________________ "How I learned to stop worrying and love the OHC Pontiac L6"  The Silver Buick- '77 Skylark coupe w/455, SPX, MegaSquirt 3 & TKO-600 (Drag Week 2011, 2012 & 2015!) 1969 Firebird with a turbo'd Pontiac L6 controlled by a MegaSquirt 3 and backed with a microsquirt controlled 4L60e and 4.56 gears! (Drag Week 2018!) |

|

#48

|

||||

|

||||

|

Quote:

It can work, but did you sync your timing? And at RPM there's no timing shift/drift? Verified with a timing light? .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#49

|

||||

|

||||

|

On inductive delay, there's no way you can use any out of the box or recommended setting, you just flat out have to check and adjust for every application. There's no way around that. Without doing that, it can retard or advance a VERY CONSIDERABLE amount, like 25-30 degrees.

" Synchronizing the EFI timing (laptop) with the engine timing (timing light): NOTE: Temporarily disable the "Idle Spark" control (in Idle Settings). 1) Turn the distributor or adjust the crank trigger to synchronize the initial (idle) timing, then lock it down. Next, ensure timing is synchronized at higher RPM using the EFI software. NOTE: Now use the EFI software "Enable Static Timing Set". I use a Static Timing value of 25° or 30°. 2) Momentarily rev the engine, and watch the timing advance with your timing light. It shouldn't move. If timing advances or retards, adjust the "Inductive Delay" until the timing maintains itself. If the ignition timing retards, increase this value. If the timing advances, decrease this value. SUMMARY: The initial (idle) timing is synchronized by turning the distributor or adjusting the crank trigger, and locking it down. The timing at higher RPM is synchronized by adjusting the Inductive Delay in the EFI software. The first synchronization is physical, and the second synchronization is electronic (Inductive Delay). Believe the timing light above all else, it's always the real timing (if there's a discrepancy). When finished, the timing as viewed on the laptop, should match what you see with the timing light, at all RPM. Once the ignition timing is fully synchronized, the Timing Table can be tuned for each application." This is not something you can guess at. If this isn't right, you will battle your tune into infinity, it will never be right. .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

| The Following User Says Thank You to HWYSTR455 For This Useful Post: | ||

|

#50

|

|||

|

|||

|

The crank trigger is 4 magnet - so yes single pulse/fire is the correct software setting. Same as the out of the box dual sync, well sort of. The ECU reads the wired crank sensor from the custom harness that ties into the 10 pin- this provides the remote crank trigger pulse to the ECU rather than getting it from the dual sync. As COP is used, the dual sync also lets the coils know TDC of # 1, and of course also the cam signal.

So yes, pretty much the same software wise as the out of the box dual sync, but some wiring and hardware changes. Inductive delay is easily set, we start with the default 100 msec value and calibrate on the dyno with a timing light, easy peasy.

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#51

|

||||

|

||||

|

I'm just modding the connector from the Dual Sync for the crank trigger, that plugs into the main harness ignition connector.

Difference between magnetic and hall effect is either 5v or 12v. So curious, what value did you end up with on the Inductive Delay? .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#52

|

||||

|

||||

|

Most hall effect can run on 12v too.

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#53

|

||||

|

||||

|

So you setup the sensor on the 50 degree mark? Or did the 50 degree mark on the cover timing marks?

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#54

|

||||

|

||||

|

So I will piggyback the one connector and switch back to the dual sync if I need to.

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#55

|

|||

|

|||

|

For the wiring, I started with Holley mini-harness P/N 558-431 and cutoff the 3 pin cam sync connector, replacing it with a 10 pin connector to plug directly into the dual sync. The provided crank trigger connector is plug and play for the Hall effect sensor (P/N 554-118), and the third 10 pin connector plugs right into the Holly main harness. So pretty simple. This mini-harness is about $80, so much cheaper to make your own if you're so inclined.

After initial static timing adjustment by moving the crank trigger bracket, the dynamic timing deviation from idle to 3500 rpm was about 3 degrees, I'll have to check the laptop to see what this was for inductive delay, but not much. I have typically not seen much deviation with crank mounted triggers as you are directly reading the crank, different story on the dual sync - especially if the timing chain is worn. Every engine is different though. ATI provides magnets on the balancer shell however many and wherever you want. I specified 4 magnets with a 50 degree reference angle, so the first magnet is at 50 degree BTDC. You just align the balancer (and magnet) to 50 deg BTDC on the timing cover "zero" mark, and the 2nd magnet at 90 degrees clockwise is where the sensor is mounted. This is pretty straightforward, the next step is setting the cam sync to accommodate your reference angle (whatever you choose). If you have a dual sync, whatever you do, do not use the reference angle and just set the balancer there and light up the cam sensor LED. The formula for setting the (dual sync) is [Ref angle]+[90 degrees(pulse angle for V8)]+[Pulse Angle/2]= Crank position in degrees. If you have a remote crank trigger and use the dual sync, and try and follow the Holley instructions (for dual sync) the engine will not run. In my case with a 50 degree reference angle, the balancer must be set at 185 degrees BTDC to calibrate the cam sensor LED.

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

| The Following User Says Thank You to darbikrash For This Useful Post: | ||

|

#56

|

||||

|

||||

|

Quote:

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#57

|

|||

|

|||

|

If reference angle is zero, then we are left with 90+(90/2), or 90+45 so it would be 135 degrees.

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#58

|

||||

|

||||

|

Yeah I fat-fingered that, was doing 185-50.

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

| Reply |

|

|