| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#21

|

||||

|

||||

|

Rock guard for 1/2" line, example:

https://4lifetimelines.com/products/ltgg12-16 Others make it too, not hard to find. $30 for 16 feet is inexpensive, if you feel you need it. .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#22

|

||||

|

||||

|

1/2 aluminum fuel line is readily available at Summit, Jegs etc. It's easy to bend and will last longer than rubber steel braided line. And it does come in a roll.

__________________

Tim Corcoran |

| The Following User Says Thank You to Tim Corcoran For This Useful Post: | ||

|

#23

|

|||

|

|||

|

Isnt the ni-cop line supposed to be better than aluminum, & easier to work with?

|

|

#24

|

||||

|

||||

|

It's very very very easy to work with. I use it a lot.

__________________

"Those poor souls have made the fatal mistake of surrounding us. Now we can fire in any direction" 1970 Trans Am RAIII 4 speed 1971 Trans Am 5.3 LM7 1977 Trans Am W72 Y82 1987 Grand National |

| The Following User Says Thank You to 72projectbird For This Useful Post: | ||

|

#25

|

|||

|

|||

|

Quote:

Looks like hardline ID is all over the place as well. I've seen anywhere from .3 to .34 for 3/8's in steel, stainless and aluminum. Aluminum tending to have the smallest ID. My lived experience with a car that gets driven in changing climates and often is that the PTFE hose has held up well. Right at about 30k miles since 2015 on Earles Push lock stuff. Summer, winter, dry and wet. Of course YMMV.

__________________

-Jason 1969 Pontiac Firebird |

|

#26

|

|||

|

|||

|

If/when I change to a in tank pump set up I will most likely use that for the return line. Where do you buy it at? couldnt find it at places like summit.

|

|

#27

|

||||

|

||||

|

I thought I got all mine from Summit. I'll look around and see if I can find it

__________________

"Those poor souls have made the fatal mistake of surrounding us. Now we can fire in any direction" 1970 Trans Am RAIII 4 speed 1971 Trans Am 5.3 LM7 1977 Trans Am W72 Y82 1987 Grand National |

|

#28

|

||||

|

||||

|

Quote:

We are talking a "tunnel" here, not a flat plate. 1/2" measured "outside diameter" tubing will be .500" when measured with a caliper. I have seen this mistake posted on the board many times over the years. And here it is again. TV

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#29

|

|||||

|

|||||

|

Quote:

Far as I know, the concern with aluminum and copper tubing is vibration--the tubing is subject to work-hardening and then the hardened sections crack and leak. Note that I'm talking about "real" copper tubing, not the better, more expensive "NiCopp" nickle/copper alloy. Quote:

We did have some problems, nearly always resulting from The F'n New Guy who didn't pay attention when I told him/her how to do things. The second most-common problem was Aeroquip -4 female hose ends cracking from being over-tightened. In short, except for what I consider to be a questionable design decision on the Dash 4 hose ends leading to them being overly-sensitive to installation torque (the sealing surface was a radius rather than a flat taper, so it could be used on 37 degree tapered fittings as well as 45 degree tapers) there is NOTHING wrong with "JIC" as long as you aren't using it on an aeroplane or spacecraft. For "ground transportation" they're Friggin' Wonderful. Now--and I've gone off on this previously--There is no such thing as "AN" or "JIC" any more. REAL "AN" is an obsolete standard for AEROSPACE/MILITARY use, "Army/Navy". Similarly, "JIC" was "Joint Industry Council", again an obsolete set of standards. The parts looked the same, and it was possible to use the high-grade, aerospace stuff in an application that only needed "industrial" quality--the threads were the same size and thread pitch, both used 37 degree tapers. They'd screw together just fine. The aerospace-quality stuff cost even more than the industrial-grade, and that is plenty expensive. Both the Aerospace-grade items and the similar-looking "industrial" versions are now covered by SAE standards. If someone is trying to sell you "AN" fittings, they're almost certainly actually providing industrial-grade stuff, that used to be considered "JIC" but isn't any more. Summit, for example, is NOT selling spacecraft/fighter-plane fittings out of their stock. Summit also does not sell "$400 toilet seats" and "$2000 coffee makers", either. Leave that to Government suppliers. Quote:

Quote:

I own a roll of some other NiCopp tubing sizes, but I haven't worked with it. I have no idea how my tooling would flare other sizes. Quote:

PIPE is measured by the ID. So 1/2" pipe would have a nominal ID of 1/2 inch. Of course, most commonly-available iron pipe and iron pipe fittings/reducers/elbows are now coming from China, the threading is terrible and the ID is roughly-formed (it never was beautiful.) Brass pipe, elbows, reducers, etc., is formed nicely, also comes from China. The ID is closer to the nominal size. TUBING is measured by the OD. So 1/2" tubing has a 1/2" OD, and the ID varies with the wall-thickness of the tube. Thinwall tube has a larger ID, thickwall tube has a smaller ID. The thickness of the wall is dependent on the material it's made from and also the pressure it's expected to take. So it's no surprise that aluminum tubing would need a thicker wall than steel, or it's rated for lower pressure, or both. When The Bus Company started building CNG- and LNG-fueled buses, we started getting acquainted with Swagelok fittings and the thickest-wall tubing I'd ever seen. But that's to be expected when the fuel is under 2000 psi plus some safety margin for the plumbing. HOSE is kinda-sorta based on TUBING sizes, specifically a more-or-less equivalent to a similar-ID tube. And in the high-quality world, "AN", "JIC" or the equivalent modern SAE standards, it's usually described in sixteenths of an inch--a "Dash 4" hose is 4/16 or 1/4-inch, roughly equivalent to the fluid pathway of "typical" 1/4" tubing. Dash 8 hose is 8/16 or 1/2 inch, roughly equivalent to the fluid pathway of "typical" 1/2" tubing. It makes me crazy when folks call plumbing "line" "lines" or "hardline" . Lines are imaginary objects in geometry. I try to make a point of using the terms "pipe" "tubing" or "hose" to describe my plumbing. Are there exceptions to this description of "pipe" and "tubing"? Sure. Exhaust "pipe" is sometimes sold by ID and sometimes sold by OD, to make it easy to build slip-fit "lap joints". Are there hoses that are not spec'd to be similar to typical tubing? Sure. Is some plastic tubing flexible in a way you'd expect from hose? Sure. Last edited by Schurkey; 01-29-2024 at 02:06 PM. |

|

#30

|

||||

|

||||

|

Quote:

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#31

|

||||

|

||||

|

Schurkey, you are correct on many and most comments, but some people use 'familiar' or 'common' terminology so they're not mistaken.

As for AN/JIC, I believe thread tolerance was once difference between the two, and have experienced 'packaged JIC' fittings that required close attention and patience when screwing them together. I generically say JIC to differentiate between fittings that either are not marked 'AN' and/or are generally 'less expensive' (cheap). Which is obviously not 'correct', but most can relate. In the automotive aftermarket, the term 'AN' is widely used, even if it is outdated. You walk up to someone at a SEMA booth and ask them for a 8/16 hose fitting you will get laughed at. With all that said, please continue to provide your comment/education, you are a wealth of knowledge and am very appreciative you share! Mean that sincerely. .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#32

|

||||

|

||||

|

The 1/2" Ni-cop tubing is what I've chosen. It's fairly thin-wall at .028" so the ID should be .440-ish and I'm a bit of a "if some is good, more is better" kind of guy...I'm just wired (weird) like that. I probably don't need it as I'm damn near certain up to 850hp or more can be supported by the system I'm building.... lol. Thanks for the responses. A good education for me and others regarding the differences between "hose" and "pipe" or "tubing", and the differing/varying ways they're sized even when nominally, they ought to be the same. Moral of the story is just know what you're buying and caveat emptor and all that rot.

|

|

#33

|

||||

|

||||

|

Not really enough information to provide exact recommendations, but for sure more is better than less with these things.

In tank pump is good, but what is the output of the pump in GPH? What pressure unregulated? Where are you mounting the regulator? Is it a bypass style regulator? On the output side of the pump you can get away with less. I'd still do 1/2" metal lines for the main run or the better -8 if you are going to hose. I've set up quite a few systems here over the years but most have had pumps mounted outside the tank. No problem at all running -8 from tank to pump, then -6 from the regulator to the carb, even a Q-jet, but in most cases I'll still do -8 everywhere just for simplicity in buying hose and fittings.. I've come to like the push-loc fittings and black hose instead of the pretty colors offered. You'll also find a wide variety of hose available, from simple braided line to teflon core with "alligator" hide on to help prevent rips, tear and wearing where it lays on something.....

__________________

If you can read this, thank a teacher. If you can read this in English, thank a Veteran! https://cliffshighperformance.com/ 73 Ventura, SOLD 455, 3740lbs, 11.30's at 120mph, 1977 Pontiac Q-jet, HO intake, HEI, 10" converter, 3.42 gears, DOT's, 7.20's at 96mph and still WAY under the roll bar rule. Best ET to date 7.18 at 97MPH (1/8th mile), |

|

#34

|

||||

|

||||

|

Quote:

Last edited by 65 Lamnas; 01-30-2024 at 02:44 PM. |

|

#35

|

||||

|

||||

|

Yikes, that's a lot of pressure.

Test the system once installed. It needs to be able to fill a gallon jug under 20 seconds and you'll be fine at that power level. I love not having a suction line to the pump. Keeps things simple and you don't have to worry nearly as much about fuel delivery to the pump or the pump heating up as it's sitting in the fuel to help keep it cool......

__________________

If you can read this, thank a teacher. If you can read this in English, thank a Veteran! https://cliffshighperformance.com/ 73 Ventura, SOLD 455, 3740lbs, 11.30's at 120mph, 1977 Pontiac Q-jet, HO intake, HEI, 10" converter, 3.42 gears, DOT's, 7.20's at 96mph and still WAY under the roll bar rule. Best ET to date 7.18 at 97MPH (1/8th mile), |

| The Following User Says Thank You to Cliff R For This Useful Post: | ||

|

#36

|

||||

|

||||

|

Is your regulator able to pass that much psi to get it to carb territory? Are you restricted to using 1 of those 2 pumps?

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#37

|

|||

|

|||

|

when i did the fuel tank/line update back in '18 i went with Earl's #8 lines/fittings

PTFE hoses, no fuel smell, not braided, super strong, heat resistant, etc well worth it so easy to work with, but do get the kit to test connections, sometimes getting the ends sealed properly takes a little time, or you can find out the hard way if you wont mind fuel leaks and the mess/smell it was their upper end stuff and well worth it, super flexible too, WAY easier than braided, again NO smells, and now i can run what ever fuel i want without issues. i'm using the aeromotive tank kit with the regulator and setup the return feed too i needed that once i moved to the dessert area.... stay within your budget and follow the advice on here, as there's a lot of good ones i can't believe the costs of things now, so just remember safety and budget. |

|

#38

|

|||

|

|||

|

Quote:

I'm assuming your chosen fuel pump is something like this? https://walbrofuelpumps.com/450lph-w...0267.html.html Here's one thing to think about. Fuel systems, more isn't always better if it's too much. If your engine makes 550hp and the fuel pump feeding it is supportive of something like 850 hp, you can create issues for yourself. Except for pumps designed to work with PWM controllers, the pumps wants to live in a specific pressure range and voltage. This may cause you to pass a lot of fuel back to your tank. If the return system is not designed properly, you can create pressure in return lines that causes pressure creep at your regulator. Additionally the large volume of fuel moving through the tank and system can collapse the tank if it's not vented properly. Point being, if you don't need enough fuel to support 850hp, I wouldn't necessarily give it that much fuel. Instead, select a pump that would be running at about 70-80% duty cycle for your given hp needs. At 600 hp, you are going to need roughly 60gph, or a little less depending on how much fuel you're giving the engine. I'd be looking at a Walbro 255 or 340. Especially at the pressures you need for your carb, the Walbro 255 would be a good choice for your combo, but doesn't necessarily provide you much future growth potential. The 340 would, while also not being so massive as to potentially cause fuel system headaches.

__________________

-Jason 1969 Pontiac Firebird |

| The Following User Says Thank You to JLMounce For This Useful Post: | ||

|

#39

|

||||

|

||||

|

Quote:

https://rickstanks.com/shop/#!/Ricks...gory=139929319 |

|

#40

|

|||

|

|||

|

Quote:

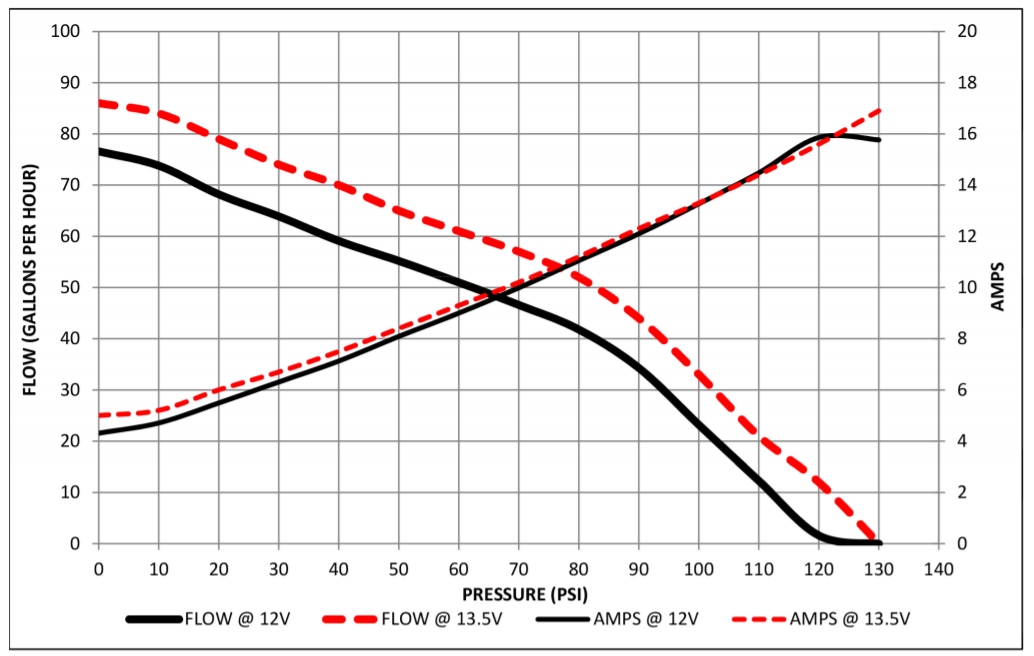

Here is the flow chart. Fat black line is fuel flow, narrow black line is amp draw.  Since you're running this with a carb, you're pretty close to free flow where this pump is flowing a lot of fluid. At 58psi which is common for most current aftermarket EFI systems, it's flowing enough fluid for about 600hp.

__________________

-Jason 1969 Pontiac Firebird |

| Reply |

|

|