| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#1

|

|||

|

|||

|

I’m selecting a cam for my 421 Tri-power motor, and looking for any suggestions. I called around to the usual cam companies, Bullet, Comp Cams, Lunati, etc. and of course each company had a totally different suggestion with no two the same- not even close.

Given the differences of opinion, I am trying to use simulation tools to narrow the choices down. As this is a 100% street motor, I have posted in the Street forum, if this topic is better suited to the Race Forum, feel free to move it. There is some discussion on other forums regarding others that are using 1D simulations and calculators to select cams, and this sounds to me like a better approach than asking for general opinions. I am using Engine Analyzer Pro to try and narrow down the field. This seems like a pretty good tool, but my use with it so far is pretty superficial, just using the HP and Torque RPM graphing, with little use of the cyclic graphing outputs (so far). I suspect much of the value in these types of simulations lies in the cyclic outputs such as intake and exhaust flow velocity, and other metrics that govern cylinder filling. Here are the particulars of the engine setup: -Bore 4.155”, stroke 4.0” (433 CID) -Rod length 6.625 -C/R 9.5:1 -Ported cast iron heads (SD Performance) Flow test @ 28" Intake Exhaust % of intake port Ported Cast Iron D ports, Pontiac (CFM) % of exhaust flow to intake. Lift, inches 0.100 73.2 64.9 88.7% 0.200 148.5 122.7 82.6% 0.300 204.8 158.7 77.5% 0.400 237.9 181.9 76.5% 0.500 259.3 201.7 77.8% 0.600 265.4 219.5 82.7% -2.11 Intake valve, 1.77 exhaust valve diameter -Chamber volume 87 CC’s -Flat top custom piston -Exhaust, header, 1.75” primary, 3” collector. -Tri-Power carbs with port matched aluminum intake -3900# car, OD manual transmission, 3.9:1 final drive ratio- daily driver street only no strip. -Min 14” vacuum at idle desired (Power brakes) -91 Octane CA pump gas (10% ethanol) Beyond these specs, I am not interested in using a roller cam, and I am concerned that a wide LSA cam is not the right direction to go for this motor. So I’m looking for any modeling suggestions for using Engine Analyzer Pro more effectively, and any cam recommendations which I can run to see how they stack up. If there are any better tools for cam selection/simulation, that might be interesting as well. So here is what I have so far. I have setup the Engine Analyzer Pro sim tool to include the above mentioned parameters, and setup a cylinder flow table representing the SD Performance cast iron head using the flow data for my heads provided by Dave Bisshop. For the cam, I am just using the seat duration, lobe lift, LSA, and duration at .050 and .200 lift (when available). So far I have run more than a dozen cams, and of these three rise to the top: - The Lunati -702 cam, 219/227 @ .050, lift .468/.489 112 LSA - The Lunati -703 cam, 227/233 @ .050, lift .489/.504 110 LSA - Custom Grind, David Vizard, Comp Cams Lobe # 5445, 230 @.050 (single pattern) .488 lift, 106 LSA All cams above are HFT, and lift is at 1.5 rocker ratio. Some solid lifter cams from Bullet were examined: GRIND PON 276/286H112+4 DUR @ .050 221/230 LIFT .454/.454 LSA 112 INT C/L 108 and from Mike Jones: GRIND PONT455 M73359-74359-110 DUR @ .050 248/252 LIFT .538/.538 LSA 110 Based on simulation, these solid cams did not perform as well as the two Lunati's. And last but not least, I decided to pop for the $150 cam selection fee from David Vizard, based on all the controversial posts on Speed Talk regarding his supposed system or formula for simplified cam selection. So I sent him all the pertinents, and he came back with his suggestion. Here it is, verbatim, what $150 buys you: Quote:

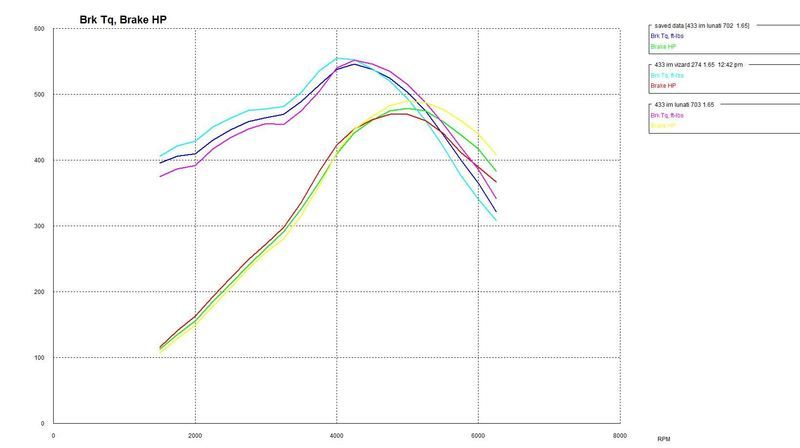

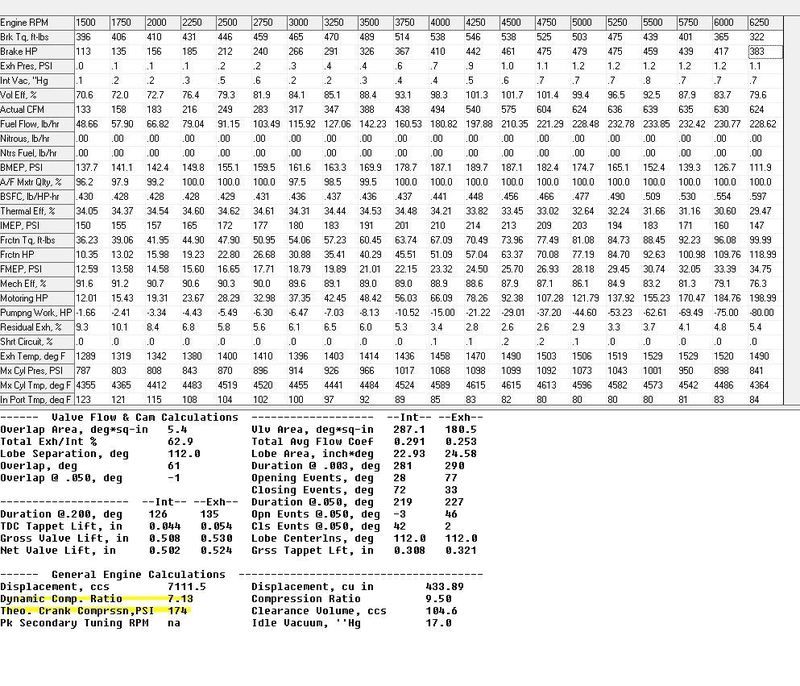

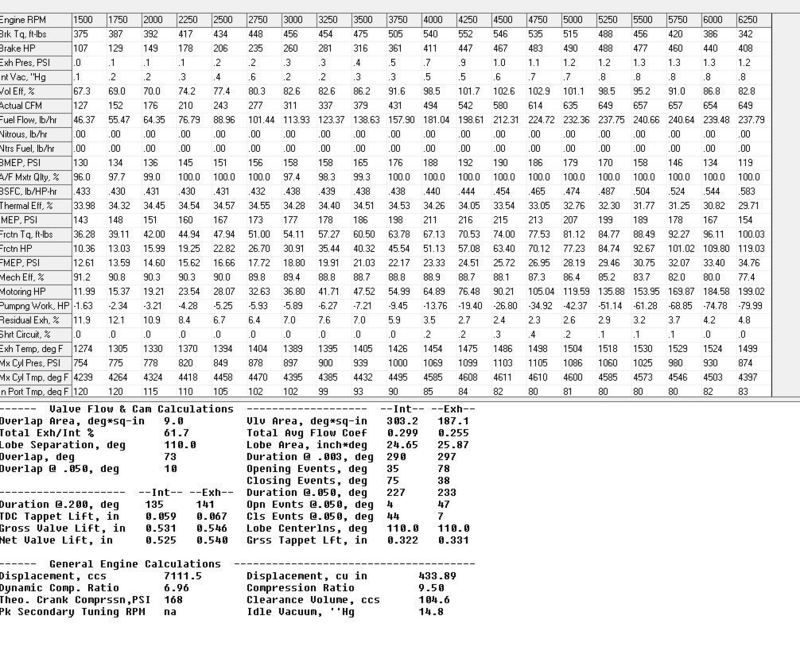

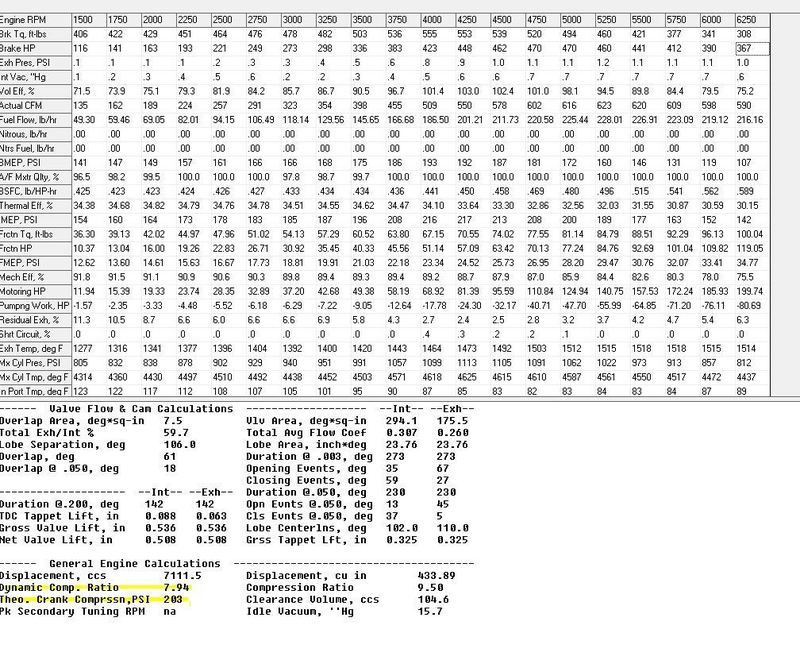

This single pattern configuration would seem to make some sense if we look at the cylinder head flow data, the exhaust flows ~ 80% of the intake, so perhaps a single pattern cam makes some sense here. Here is a comparison graph of the top three cams I simulated, the Lunati -702, the Lunati -703, and the Vizard XE274. As Vizard recommended a 1.65 rocker ratio for his cam, I have set all three cams to this same ratio for comparison. Turns out the Vizard cam performs pretty well at least with regard to torque production- it outperforms the two Lunati's below 4100 rpm.  Here are the results tabulations, cam by cam. Note the dynamic compression ratio and the static cranking pressure for each cam are highlighted, also we can see predicted idle vacuum for each cam. Lunati -702 HFT  Lunati -703 HFT  Vizard XE 274 Custom:  Looked at from this perspective, I would be very concerned the Vizard 274 cam would have detonation on 91 octane pump gas. Another comment would be just the general good performance of both Lunati cams, with low dynamic compression ratio and good idle vacuum. Open to suggestions, and any insight into modeling with Engine Analyzer Pro.

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#2

|

|||

|

|||

|

I would have charged you $149....

Ok, there are more than a few points I look at when I choose a cam: 1. Where do you want the hp peak rpm to be? Obviously your car is heavy, but you have a manual trans and a deep rear gear, which helps out considerably. You shouldn't have to cut the duration short to help with lower rpm power. 2. You obviously need vacuum. 3. You have excellent intake/exhaust flow. High 70's/low 80's offers a really nice setup. I base the duration splits on this. 4. You have cast iron heads and 9.5:1 SCR, so I would keep the DCR under 8:1. 5. Lift can be based around the head's performance. Obviously, the flow isn't backing up on you at .600" lift, so I would aim there. 6. LSA isn't the first input that I look at, but it is important. Keep in mind that a lot of cam grinders will offer high advertised durations to help with octane requirements or to use a bigger cam, but they will widen the LSA to keep vacuum up. I feel that if you can help it, a tighter LSA is best for making torque. I've repeatedly seen wider torque curves on the dyno with tight LSA's. I'm not advocating going as low as David suggested, but 109-110 is often a sweet spot. Computer sims aren't the end-all/be-all, but you can get an idea of what each camshaft will do. Give me a bit and I'll come back with my own recommendation for giggles. Where would you like the peak hp to be at? 5500-5700 would be a sweet spot, IMO. Last edited by blykins; 04-02-2016 at 07:12 PM. |

|

#3

|

|||

|

|||

|

Forgot to ask....

What's most important to you? Peak hp? Peak torque? Average hp or torque? |

|

#4

|

||||

|

||||

|

I have met Jim Hand and Cliff, I know how their "spec'd" engines perform. I know how well S.D. Dave's stuff performs. I'd trust Paul K., Brent, GTOFreek, and others here to pick a cam and engine parameters.

To me David V. seems to live in another world. I've read a lot of his stuff, he's NOT the performance answer man, especially pertaining to a street/strip Pontiac powered automobile!!! Maybe in things more race oriented, sometimes... I'd throw David V's stuff out the window, and talk to some real Pontiac experienced folks, period!!! Computer generated engine parameters can be interesting to play with, but also have no real world comparison. Good old fashioned machine work, proper selection of parts, properly installing them, and tuning ability are the things that make the deal. My engine builder could build a common 350 Chevy, the dang thing ran better than most could imagine, got good MPG, and w/ preventive maintenance could last a LONG time!

__________________

1977 Black Trans Am 180 HP Auto, essentially base model T/A. I'm the original owner, purchased May 7, 1977. Shut it off Shut it off Buddy, I just shut your Prius down...

|

|

#5

|

|||

|

|||

|

It's nice to look at all those numbers BUT as you said this is the street section and you intend to street drive it.I work backwards when trying to pick a cam for that.Where will you do the most driving?At 40-50 around town or 65-70 on the highway.If you pick too much cam and your driving is mostly at 50 you won't be able to use your OD,you will be pulling back a gear.Lots of this stuff will be trial and error if you start too big or IMO too tight of lobe.My 63 421 lemans has a Tremic and I have been down this road with our cal gas.Good luck with your choice.Tom

|

|

#6

|

||||

|

||||

|

Looks like you have the intake center lines straight up on the Lunati sims. Try the 112 @ 108 ICL and the 110 @ 106.

__________________

68 GTO,3860# Stock Original 400/M-20 Muncie,3.55’s 13.86 @ 100 Old combo: 462 10.75 CR,,SD 330CFM Round Port E's,Old Faithful cam,Jim Hand Continental,3.42's. 1968 Pontiac GTO : 11.114 @ 120.130 MPH New combo: 517 MR-1,10.8 CR,SD 350CFM E's,QFT 950/Northwind,246/252 HR,9.5” 4000 stall,3.42's 636HP/654TQ 1.452 10.603 @ 125.09 http://www.dragtimes.com/Pontiac-GTO...lip-31594.html |

|

#7

|

|||

|

|||

|

And the 110 on a 104 as well.

|

|

#8

|

||||

|

||||

|

It would be more ideal to have flow values with the intake bolted on.

I dislike Comp XE lobes. I would rather go with Comp Dual Energy Lobe 5002 283 advertised 233 @.050 146 @.200 .320 lobe lift For a 433 to run about 6000 RPM I would look for around 63 degrees of overlap (advertised). For another solid flat option: ULTRADYNE Intake Lobe F18 280 adv 247 @.050 159 @.200 0.3500 lobe lift Exhaust Lobe F8 284 adv 251 @.050 162 @.200 0.3533 lobe lift I like Mike Jones, his lobes are unique and run really strong. Last edited by pastry_chef; 04-02-2016 at 08:12 PM. |

|

#9

|

|||

|

|||

|

Quote:

|

|

#10

|

|||

|

|||

|

I think the Tri-Power is largely going to dictate this. This is of course a 2 bbl motor for 80% of it's duty cycle, when the end carbs open the cam should hit hard. I'm not interested in time slips, just a hard hitting motor when the end carbs open. I think this means average torque is the most important parameter, with an all in HP band at 5500-5700 as you suggest.

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#11

|

|||

|

|||

|

Try something like this...

230/234 at .050", 274/278 advertised, 110 LSA on a 104 ICL, .540"/.547". Trying to get my daughter ready for bed so I haven't ran the numbers, but see where that puts you. |

|

#12

|

||||

|

||||

|

This also might be a contender.

5800 RPM ULTRADYNE Solid flat 1.5 roller rockers. 109 LSA - install intake at 106 centerline Intake F9 276 adv 243 @.050 153 @.200 0.3450 lobe lift Exhaust F18 280 adv 247 @.050 159 @.200 0.3500 lobe lift |

|

#13

|

|||

|

|||

|

Quote:

Quote:

Quote:

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#14

|

|||

|

|||

|

Forgot to mention, 140/147 @ .200". 1.65 RR.

|

|

#15

|

||||

|

||||

|

Quote:

|

|

#16

|

||||

|

||||

|

Quote:

Stan

__________________

Stan Weiss/World Wide Enterprises Offering Performance Software Since 1987 http://www.magneticlynx.com/carfor/carfor.htm David Vizard & Stan Weiss' IOP / Flow / Induction Optimization - Cam Selection Software http://www.magneticlynx.com/DV Download FREE 14 Trial IOP / Flow Software http://www.magneticlynx.com/DV/Flow_..._Day_Trial.php Pontiac Pump Gas List http://www.magneticlynx.com/carfor/pont_gas.htm Using PMD Block and Heads List http://www.magneticlynx.com/carfor/pont_pmd.htm |

|

#17

|

|||

|

|||

|

Quote:

I'm tempted to try this cam, but I'm afraid it will ping.

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

|

#18

|

||||

|

||||

|

Quote:

http://forums.maxperformanceinc.com/...d.php?t=430357 Take note of the performance. I like David Vizard, I own most of his books. He is most likely correct in his recommendation. BUT going with 106 LSA *may* be taking a risk you will have lower vacuum than 14 " Also - Pump gas can be much like engine dynos, the chemistry can vary with different brands / locations. Vizard ran a test and found significant power differences with different brands of pump gas. As for Speedtalk and 128. There are some who may very well be intelligent, but they need some counselling. Posting scores if not hundreds of rebuttals about how 128 does not scale correctly when pushed to extremes. Not worth anyone's time! I don't know anyone building an engine with 8 inch bore and 8 inch stroke. A person can make their point, perhaps make it a second time, then they should move on! Last edited by pastry_chef; 04-03-2016 at 05:52 AM. |

|

#19

|

||||

|

||||

|

If you WILL have your can nitrided and will use lifters with an oiling hole.

Good quality rockers, pushrods and valve springs. 1.5 ratio rocker One more: Comp Cams Solid Flat --------------------- GRI intake lobe 16206 277 advertised 250 @.050 162 @.200 .367 lobe lift XTX exhaust lobe 6404 280 advertised 246 @.050 153 @.200 .347 lobe lift 110 LSA - intake at 106 centerline. |

|

#20

|

||||

|

||||

|

Choosing a cam for your engine will certainly be a tall order.

The trump card is requiring 14" vacuum at idle speed (750-800rpm) and getting enough cam in the engine to effectively use 265cfm head flow. The 9.5 to 1 SCR isn't helping. I've done a half dozen 428 builds in my time and they are excellent engines, much more efficient than the 4.21" stroke engines and really respond well to tighter LSA than what we usually select for similar 455 engines. Recently we've been involved with two 428's, both were dyno'd and both used unported KRE aluminum "D" port heads at 260cfm intake flow. The first one we did used 74cc heads and 10.6 to 1 compression. We used a custom ground HR cam with Comp XFI lobes 236/244 on a 110LSA. It made 12" vacuum at 1000rpm and 497hp/540tq with peak HP at 5800rpm's. The second 428 used 87cc heads with less compression and made 480hp/528tq with a HR cam 236/244 on a 111LSA. Since it ended up in a 4 speed application it has acceptable idle quality but pretty "lumpy" below 1000rpm's. Neither one of those cams would meet your vacuum at idle requirements as they were lower at 1000rpms with more compression, and compression is a KEY player in vacuum production at idle speed. Since you are using a flat cam, and 9.5 to 1 compression and 433cid and 265 cfm head flow a pretty "hefty" cam will be needed to effectively work with those parameters. Problem is that 9.5 to 1 compression and a big cam will result in pretty "low" vacuum at idle speed. I'd look closely at an older Ultradyne cam that specs at 231/239/110 specs, and put Rhoads lifters on it. Use the V-Max variety and set them at .020" clearance. This might get it done, but I really don't think you'd see 14" vacuum at idle without throwing a LOT of timing at the engine at idle speed. You can always drop back to 1.5 rockers and loosen up the valve lash a bit if more vacuum at idle is needed.......Cliff

__________________

If you can read this, thank a teacher. If you can read this in English, thank a Veteran! https://cliffshighperformance.com/ 73 Ventura, SOLD 455, 3740lbs, 11.30's at 120mph, 1977 Pontiac Q-jet, HO intake, HEI, 10" converter, 3.42 gears, DOT's, 7.20's at 96mph and still WAY under the roll bar rule. Best ET to date 7.18 at 97MPH (1/8th mile), |

| Reply |

|

|