| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#1

|

||||

|

||||

|

So before I go about assembling my engine this weekend I have a question about installing the timing set. I've done some reading but apparently nothing is clicking lol my new timing set has the adjustable crank sprocket (+ or - 4 degrees.) I'm wondering if I should install my cam dot to dot, or should I advance it? Here are my engine specs and cam card:

69 YD 400 Std bore Stock bottom end Cast #46 heads with screw in studs and new springs, locks, and retainers for the cam Lunati 268/276 cam Borg Warner ST10 3.55 rear gears Here's a link for the cam card: http://www.lunatipower.com/CamSpecCa...rtNumber=60903

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

|

#2

|

||||

|

||||

|

The camshaft should be degree'd to 106 ICL per the manufacturers recomendations.

It is NOT a good ide to simply advance the cam and put the engine in service. Degree the camshaft with the timing set dot to dot and compare to the manufactures recommendations, then move it if/as needed to get it to 106ICL or very close to that number. This is an area of engine building that should get considerable time to make sure it is right. I see WAY too many folks having all sorts of issues, including not making nearly the power they think they should be, and it starts with putting the cam in the correct position during engine building......Cliff

__________________

If you can read this, thank a teacher. If you can read this in English, thank a Veteran! https://cliffshighperformance.com/ 73 Ventura, SOLD 455, 3740lbs, 11.30's at 120mph, 1977 Pontiac Q-jet, HO intake, HEI, 10" converter, 3.42 gears, DOT's, 7.20's at 96mph and still WAY under the roll bar rule. Best ET to date 7.18 at 97MPH (1/8th mile), |

|

#3

|

||||

|

||||

|

Alright, this is exactly where I get confused. So put gears dot to dot, then check cam per specs correct? Then how do I set it at 106 ICL?

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

|

#4

|

||||

|

||||

|

This is where you purchase a cam degree wheel and read a few articles on how to degree a cam...

The other option is to install the timing set "dot-to-dot," and see how it runs. If you are happy, all is good. If it feels like you are missing low-end power, you could move the crank gear to the 4 advance mark. If you are missing top end, you could move the crank gear to the 4 retard. Of course this trial and error method creates more work, and you are only guessing at this point. |

|

#5

|

||||

|

||||

|

Quote:

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

|

#6

|

||||

|

||||

|

Can I secure the degree wheel to the crank using the crankshaft bolt?

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

|

#7

|

|||

|

|||

|

Quote:

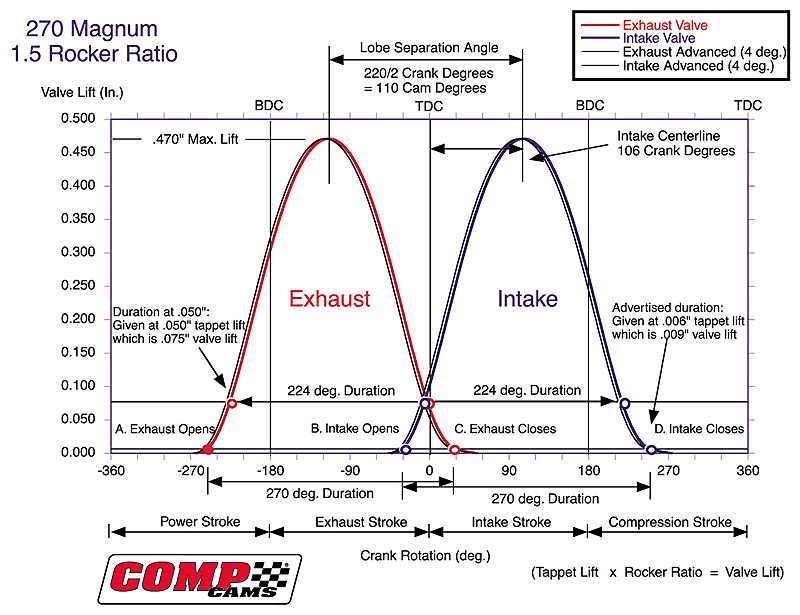

Do you understand this diagram? If not then you need to learn it so that you understand what you are doing when you degree that cam. What you are trying to do when you degree in the ICL with a degree wheel is install the cam in such a manner that the max lift of the intake occurs at the proper point in relation to TDC. In the above example the ICL is 106 degrees. That means the max lift point of the intake occurs 106 degrees after top dead center (ATDC). Simply installing the timing set dot to dot doesn't ensure that the ICL will be at 106 when you check it. You could have it dot to dot and check it and it could be 102. That means the cam is already advanced when the timing set is dot to dot. If you didn't know that and went ahead and installed the timing set using the 4 degree advanced position (and the timing set was indeed 4 degrees advanced as advertised, which is another can of worms) then the cam would be installed 12 degrees advanced at 98. If the cam in the pic was installed "straight up" the cam would be installed on a 110 ICL, because the LSA of the cam is 220 degrees. If you place TDC in the middle of the two max lift points then TDC would be 110 degrees away from each max lift point, or installed "straight up." Since 110 would be the straight up position, 106 would be 4 degrees advanced, 102 would be 8 degrees advanced, and 98 would be 12 degrees advanced for a 220 LSA cam on a 98 ICL. You never know unless you check. Last edited by Motor Daddy; 01-29-2014 at 10:13 PM. |

|

#8

|

||||

|

||||

|

Like Cliff said, it is very important to get the cam where it needs to be. This is especially true with the VooDoo cams as their lobes are offset from their centerline. That cam needs to be installed no later than 106° ICL.

Now, if the key slots are where they need to be, and the gears are accurate, you should just need the timing marks set dot to dot, with the crank gear on the zero slot[no advance, no retard]. These cams have the advance ground into them so you will usually be within 1° of where you need to be. But it needs to be checked afterwards. Don't use the advance slot on the crank gear as that will advance it 8° crankshaft degrees[or down to the 98° ICL area, not good]. If you need to advance it a couple degrees to get it right, you will need to buy an offset cam key. They make them for BB Dodge engines. Under no circumstance do you ever want to retard one of these VooDoo cams. They will be a turd. Their design needs to be advanced the full 4° if not 6°. Harold told me to install these cams anywhere from 4°-6° advanced and your good. I have used this same cam before and may have the lifter rise written down at the correct degree at work. That would help a lot to see if your close to where you need to be if you don't have the degree'ing equipment. Obviously, if you can degree it, that's what you want to do. The lobe offset is one of the reasons these cams work so good, so that's why it's so important to get it as close to 106° as you can.

__________________

Paul Carter Carter Cryogenics www.cartercryo.com 520-409-7236 Koerner Racing Engines You killed it, We build it! 520-294-5758 64 GTO, under re-construction, 412 CID, also under construction. 87 S-10 Pickup, 321,000 miles 99Monte Carlo, 293,000 miles 86 Bronco, 218,000 miles |

| The Following 3 Users Say Thank You to gtofreek For This Useful Post: | ||

|

#9

|

||||

|

||||

|

Quote:

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

|

#10

|

||||

|

||||

|

Correct, as far as ICL goes. You can't go off the open and close events on the card as the card is a computer generation, assuming a centered lobe. These lobes will vary a little bit on the opening and closing points, so that's why it's best to degree using the ICL method and not the opening and closing points.

__________________

Paul Carter Carter Cryogenics www.cartercryo.com 520-409-7236 Koerner Racing Engines You killed it, We build it! 520-294-5758 64 GTO, under re-construction, 412 CID, also under construction. 87 S-10 Pickup, 321,000 miles 99Monte Carlo, 293,000 miles 86 Bronco, 218,000 miles |

|

#11

|

||||

|

||||

|

Timely thread for me.

Paul, in your experience with these cams are they generally off by a common amount? I'll be installing a 60902 with the engine in the car and the heads on. I had planned on installing it +4 via the timing set figuring that will get me close enough but if you've found that each cam is different then I may come up with a plan B.

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - Moser 3.55 Truetrac (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

|

#12

|

||||

|

||||

|

I was specifically speaking about VooDoo cams. I have seen cams all over the place. The worst needing to be retarded 6°, to make it 4° advanced. That's why it's always best to degree them. As far as the cam card on the VooDoo's, they are usually off a degree or two, depending on their size, from what the card says. This is not a cam grind issue, but rather the computers inability to compensate for the non-symmetrical lobe.

__________________

Paul Carter Carter Cryogenics www.cartercryo.com 520-409-7236 Koerner Racing Engines You killed it, We build it! 520-294-5758 64 GTO, under re-construction, 412 CID, also under construction. 87 S-10 Pickup, 321,000 miles 99Monte Carlo, 293,000 miles 86 Bronco, 218,000 miles |

|

#13

|

||||

|

||||

|

Most of the time, it's the timing set (gears & chain) that are off, not particularly the cam.

.

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#14

|

||||

|

||||

|

Quote:

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

|

#15

|

||||

|

||||

|

Do I need a crankshaft socket to hold the degree wheel on or will the crank bolt suffice?

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

|

#16

|

||||

|

||||

|

Quote:

Many years ago, I got the basic CompCam "kit", with the small diameter wheel. I used the crankbolt, and made it work. Sometimes if I tried to turn the engine CCW instead of CW, the bolt would loosen, which made the wheel move - had to go back and re-zero the wheel. It is also hard to get the wheel PERFECTLY centered, as the hole is bigger than the bolt. I modified the wheel, cutting holes that would allow me to bolt the wheel to the damper. That made the wheel lock in place more solidly, but then the crank bolt was just partially threaded in, and you still can't go CCW.

__________________

'73 T/A (clone). Low budget stock headed 8.3:1 455, 222/242 116lsa .443/.435 cam. FAST Sportsman EFI, 315rwhp/385rwtq on 87 octane. 13.12 @103.2, 1.91 60'. '67 Firebird [sold], ; 11.27 @ 119.61, 7.167 @ 96.07, with UD 280/280 (108LSA/ 109 ICL)solid cam. [1.537, 7.233 @93.61, 11.46 @ 115.4 w/ old UD 288/296 108 hydraulic cam] Feb '05 HPP, home-ported "16" D-ports, dished pistons (pump gas only), 3.42 gears, 275/60 DR's, 750DP, T2, full exhaust |

|

#17

|

||||

|

||||

|

Right. I have the Voodoo cam one step down from the one you are installing. My understanding is that there isn't any advance ground into the cam but I guess that's why you degree it.

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - Moser 3.55 Truetrac (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

|

#18

|

||||

|

||||

|

Quote:

The vast majority of pre-ground cams will come 4 advance. There is nothing magical about that number, it is just a "safe" number that works decent for most customers, and they cam grinders are simply used to setting up their machines for that value.

__________________

'73 T/A (clone). Low budget stock headed 8.3:1 455, 222/242 116lsa .443/.435 cam. FAST Sportsman EFI, 315rwhp/385rwtq on 87 octane. 13.12 @103.2, 1.91 60'. '67 Firebird [sold], ; 11.27 @ 119.61, 7.167 @ 96.07, with UD 280/280 (108LSA/ 109 ICL)solid cam. [1.537, 7.233 @93.61, 11.46 @ 115.4 w/ old UD 288/296 108 hydraulic cam] Feb '05 HPP, home-ported "16" D-ports, dished pistons (pump gas only), 3.42 gears, 275/60 DR's, 750DP, T2, full exhaust |

| The Following User Says Thank You to Lee For This Useful Post: | ||

|

#19

|

||||

|

||||

|

Yes, the VooDoo's do have 4° advance ground into them.

What makes degreeing easier is to do it with only #1 piston installed. That way the friction is much less and you can turn the crank much easier.

__________________

Paul Carter Carter Cryogenics www.cartercryo.com 520-409-7236 Koerner Racing Engines You killed it, We build it! 520-294-5758 64 GTO, under re-construction, 412 CID, also under construction. 87 S-10 Pickup, 321,000 miles 99Monte Carlo, 293,000 miles 86 Bronco, 218,000 miles |

| The Following 2 Users Say Thank You to gtofreek For This Useful Post: | ||

|

#20

|

||||

|

||||

|

Now another question sorta related to degreeing. . .

On my 400 with the factory crankshaft, what size is the snout? So I can order a crank socket. Comp lists 2 different sockets, 1.225" and 1.385". Definitely a lot of good, useful information in this thread!

__________________

1967 GTO, 432 (428+.030), 4-bolt mains, factory Nodular crank, scat rods, icon dished pistons, Lunati HR 243/251@.050, .618/.622 lift, Edelbrock 72cc round port heads, 10.5:1, offy 2-4 intake, Edelbrock 650cfm carbs, Super T10 trans (2.64 first), BOP 10 bolt w/ Eaton posi and 3.36 gears |

| Reply |

|

|