| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

|

| Pontiac - Boost Turbo, supercharged, Nitrous, EFI & other Power Adders discussed here. |

| Reply |

|

|

Thread Tools | Display Modes |

|

|

| Pontiac - Boost Turbo, supercharged, Nitrous, EFI & other Power Adders discussed here. |

| Reply |

|

|

Thread Tools | Display Modes |

|

#21

|

||||

|

||||

|

If you wanna gain some IH for better spring selection,and more max lift clearance,just use the valves from the 4X-4h heads in those 6H heads.

That move alone will add at least +.150" IH to the 6H heads,probably more. The 400 heads valves are typically 4.980" long. The 455 heads valves are typically 4.810" long. Only catch to that "trick" is the need for corresponding longer pushrods. And should you opt to use the solid lifter cam,lifter choice can affect that pushrod length as well. Personally,for a "milder" combo,I'd opt for somewhat lower compression ratio,bit higher boost,and as much lift as I could get without running into P2V issues. Bruce & Brad's cam suggestions both are in the ballpark IMO,I'd also opt for a rocker like the HS 1.65's which measure closer to 1.7 ratio. Peak head flow numbers likely wont be too big a deal in a "budget" combo like this. The boost is where the bulk of the peak power will be coming from. 12 lbs like Baron mentioned sounds pretty reasonable IMO. But I dont claim to be a boost expert either. Just wanted to point out that valve swap deal as an option here. The OP said he wanted to use as many "on hand" parts as possible. HTH Bret P. |

|

#22

|

|||

|

|||

|

Well, I pulled the crank outta my used 455 yesterday to put a rear main seal in and lets just say the bearings were in less than perfect condition. Obviously, they've had a bit of trash run through them as well as a little bit of pitting.

The thrust also has a couple of chewed up spots on it...  So I guess keeping this super cheap is out the window and I think I'm gonna bite the bullet and rebuild her. So far I'm thinking PPR's 5140 rods and the Icon/ Keith Black forged pistons with the 15cc dish. I still wanna use the cam that I have, a solid lifter with 251/263 duration @ .050 .530/.556 lift on a 114 LSA. My heads are 4x 4h's with screw in studs, 2.11/1.66 valves and are gasket matched as well as the ports being cleaned up. The intake I have is a Torker 1 also gasket matched to the heads. From online calculators figuring in a .030 overbore, 15cc dish of the Icon's, felpro 1016's, a very rough guesstimate of being .015 in the hole, and the 97cc chamber of my 4x heads I come up with around an 8.6:1 compression ratio. I want to try and run 10lbs of boost, I think my compression ratio might be a little high but I do have an intercooler and an msd 6btm if I need to pull some timing out. I was also thinking about studding the mains instead of using the factory bolts. So how does this sound to you guys? Any recommendations on piston rings or rod/main bearings? Thanks again, James |

|

#23

|

|||

|

|||

|

If static compression works out to be 8.6:1 I dont think thats too much compression at all. Still want to pull timing out under boost.

|

|

#24

|

|||

|

|||

|

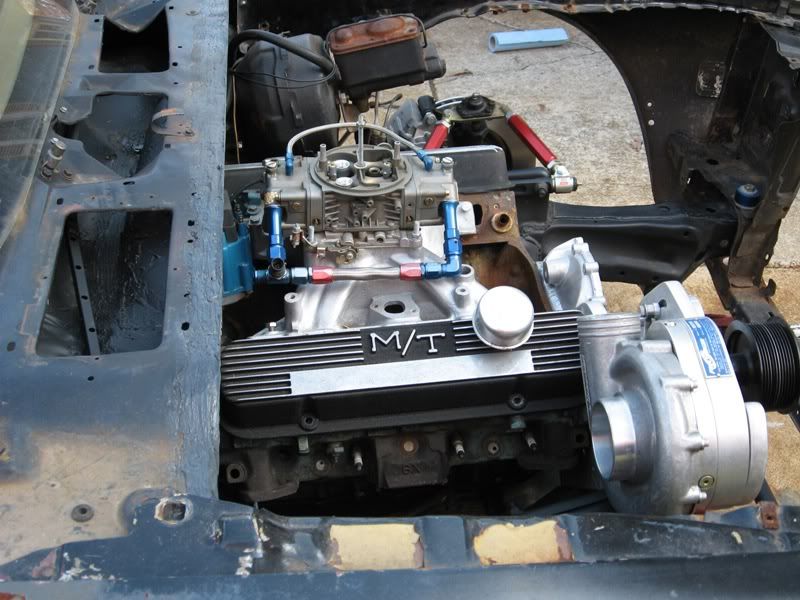

I know its been a while but I haven't quit. Things have just taken much longer than expected.

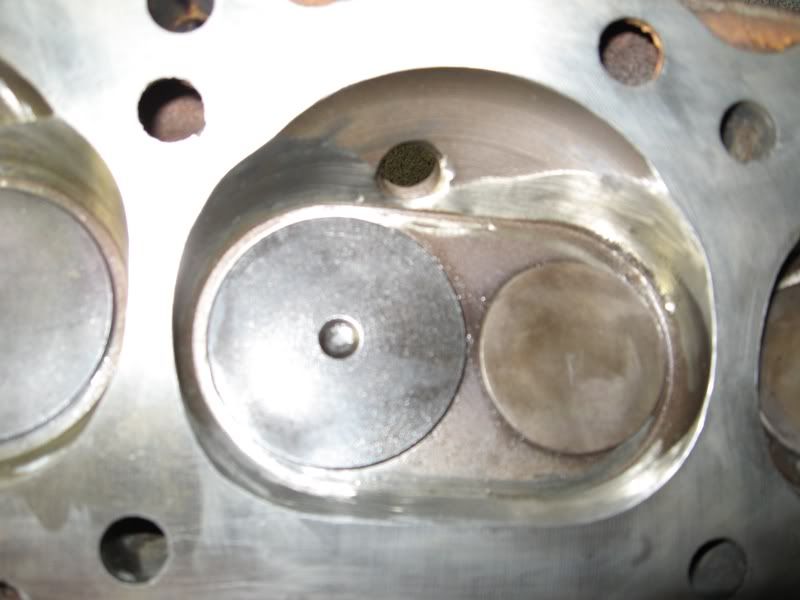

I ended up having the motor pretty much completely rebuilt. To refresh the block and crank are a 75 455 from a grandville wagon. The crank was turned .010 as well as the block being bored .030. All pontiac loaned me a torque plate for the final honing. The mains were were also studded and align honed. The pistons are the newer keith black forgings with the 15cc dish and rods are tomahawks from pacific performance racing.   The heads are 4x 4h's with screw in studs, 2.11/1.66 valves, crower 68404 springs, and some minor port work by me, mainly just gasket matching and some bowl work. Although I think they may have been surfaced before, after a cleanup cut the heads were right a 96 cc's. With the pistons .010 in the hole, and 1016 head gaskets I figured that I will have right around an 8.7:1 compression ratio. Probably a bit high for boost, but I have a huge intercooler and an MSD 6btm to pull out timing.   The cam is a solid with 251 degrees of duration on the intake and 263 degrees of duration on the exhaust at .050. Lift is .530 intake .556 exhaust, a bit more with the 1.52 rockers I will be running. The cam was degreed in per the cam card, it came in at 107 degrees instead of the 108 degrees recommended, I figured I would try it here first before I changed it.  The intake is a tomahawk from PPR, I still have to gasket match it and cut off the crossover, I also have valve cover spacers on the way so the polylocks clear the covers. Other than that and dialing in the bellhousing the motor is pretty much ready to go in. I'll try and get some pics of the engine bay in the car next week. |

|

#25

|

|||

|

|||

|

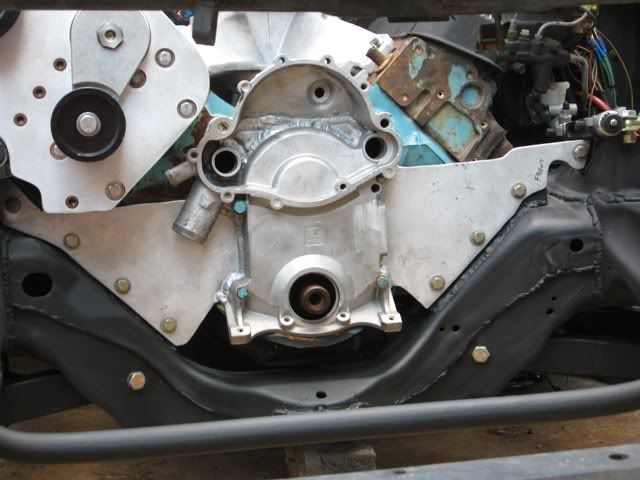

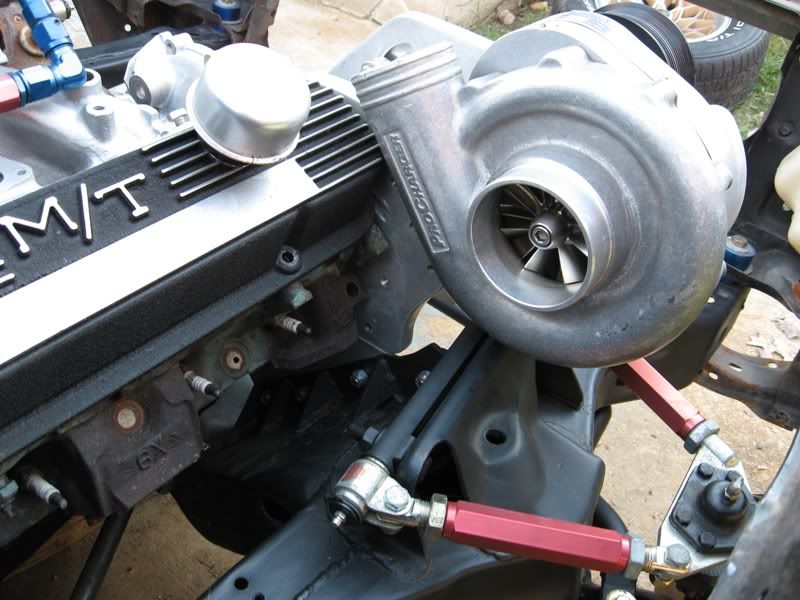

Looking VERY nice! What LSA is your new cam? Also.....I like your new motor plate welded to your timing cover.....did you do that yourself? I hear welding to cast aluminum can be tricky, not that I have any experience...lol. Is that an oil temp probe sticking out from your oil pan?

|

|

#26

|

|||

|

|||

|

Thanks, forgot to mention the lsa on the cam is 114, so hopefully it should work well with the blower.

That is an oil temp probe sticking out of the pan, the notch in the front of the pan is to clear the cross member in the chassis, due to motor set back as well as dropping it a bit lower in the car. I can only mig, I did not do the welding on the timing cover, it was tigged by a place I found locally after several other places failed. Apparently it was extremely hard to get a trouble free weld because of all the years of antifreeze flowing through the timing cover. When I had a 1/4" milled off the back to accommodate the motor plate it opened up the water pump cavity. |

|

#27

|

|||

|

|||

|

Gotcha, the timing cover looks good. I had similar issues a few years ago when I had an aluminum tower on a boat that needed welding. The aluminum had picked up contaminants from years of saltwater exposure and made it difficult to weld.

Your cam isnt that far off from mine, though mine is a more square type with identical durations and lift. Its been a great cam, and made gobs of power with the turbo so far. Dont pretend to be a cam expert and have no idea about the blower.... I have decided to use a remote oil filter setup. Its a HUGE CV-1 that uses a 2 qt HP-6 filter and has -12AN inlets and outlets. I'll be running a 3 Qt accumulator with that, and also a plate style oil cooler. All told I should be running an extra 6 Qts outside the engine, and 7 inside. I am going to mount my oil temp and pressure gauges at the oil filter mount. With the oil return lines from the back of each head and the turbo to the pan, plus oil lines to the forward mounted oil filter, and transmission cooler up front...... I think the whole motor with all that plumbing is going to begin looking like the alien in the movie PREDATOR.......with his dreadlock looking things.......lol |

|

#28

|

||||

|

||||

|

Nice project. I just read the thread fromt he begining with quite a bit of enthusiasm until the girlfriend and delay part came about.

Anyway, I admire your project quite a bit. Wanted to ask about the engine set back as I do not think you got enough into it. what about in side the car? I would guess you enlarged the trans tunnel too because of moving the trans back? What about driver position, pedals, etc? This also would move you further away from the dash and gauges or did you move it all back too? Just thinking about reaching the light switch, stereo, etc. or did you stay in the same place and just be more cramped? curious? Best to you on the engine build but, surprised you put the said limited time and money into a 455 esp. after a 400 main web failure? Would it have not been cheaper/wiser to build an earlier 400 or 389 with the thicker webs? I see the advantages to the extra inchs for some but, with your blower, should not make much a difference. Oh, like your headers too. Hoping that lifes other interests do not deter you too far from the Pontiac/car hobby. Best to you, Steve

__________________

Hundreds of Pontiacs in Az "Real Pontiacs only..no corporate nonsense!" Facebook- Pontiac Heaven Hosting- 23rd annual Pontiac Heaven weekend- Phoenix pending due to covid Pontiac Heaven Museum in process Phil 2:11 |

|

#29

|

|||

|

|||

|

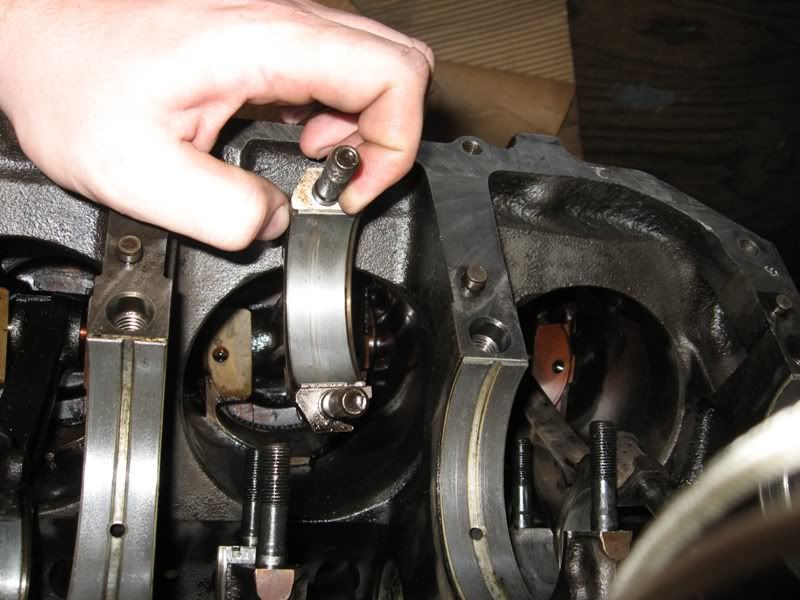

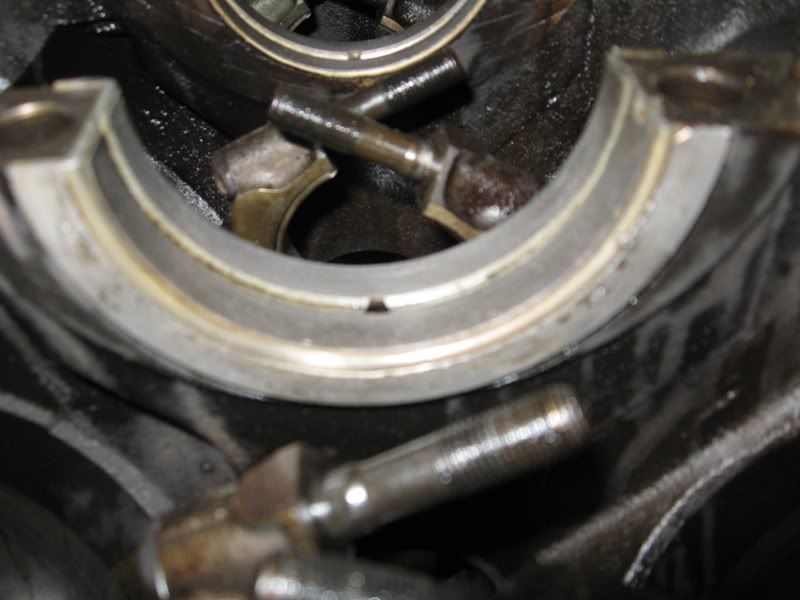

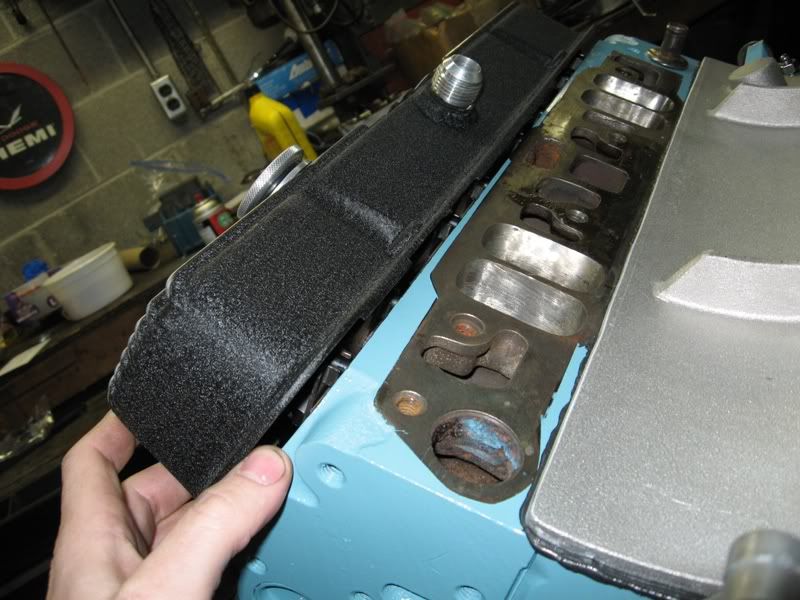

Got the valves lashed, PRW 1.52 rockers on today etc. Before anyone asks I checked each valve for clearance; I had significant problems with stock length valves. I ended up having the guides cut down some when they were cut for positive seals, I also ended up machining a slight amount off the retainers, now I have about .050 clearance on every valve.

Here is a pic of my valve covers:  And the previously mentioned clearance problems that I'm planning on solving with a 3/8" spacer. I could have probably milled some off the poly locks as well but at this point I'm tired of going to the machine shop...  Aron, I am also running a remote filter due to the fact of the headers not being able to clear the stock oil filter adapter with the amount of engine setback I have. I also plan on running an accumulator but just don't have the money for one right now. My lines from the block to the remote filter are -12, I had to make the fittings coming out of the block because I tapped the holes for 3/8 npt. I wish I would have gotten a remote filter housing with a place for an oil sending unit pressure gauge, I am having trouble fitting mine at the back of the block under the distributor. Thanks Steve, I have a 71 400 block and crank that I was originally intending on using, then I ran out of money, girlfriend, etc.. When I was planning that motor it was to be as "all out" as I could have made it. Professionally ported heads, 4 bolt mains, block filled, aluminum rods, you know what I mean. Then I found this good running 455 on my local craigslist for cheap, it re-sparked my interest in the project and the plan was to swap heads, throw some gaskets in it and get the car running cheaply. So i guess I'm kind of saving the 400 I have for more of an ultimate buildup of sorts. Although I do agree the 3.75 stroke and smaller main bearings would have probably been much better for what I'm doing. I am not trying to make the most power I can, just have a fun unique car that will surprise some people. I have some pics of when I cut the firewall out, I'll dig them up later and try to go more in depth. |

|

#30

|

|||

|

|||

|

I think this build is cool. I'd like to see what you have done on the inside of the car also. I'm doing a turbo build for my car that's moving along pretty slow too, but I figure it'll be finished when it gets finished. Nice work, Ronnie

|

|

#31

|

|||

|

|||

|

Hope all you guys doing a turbo build might also join us over on pontiaczone.com forums in the boosted section. Some good info there too and many of the same people. If you are building a car to go fast around corners as well, I'm also on pro-touring.com forums and THAT place is incredible. Some of those cars make my jaw drop.

|

|

#32

|

|||

|

|||

|

fwiw With your ICL at 107 with a new chain, chances are after break in ICL will be closer to 108.

|

|

#33

|

||||

|

||||

|

Quote:

__________________

John Wallace - johnta1 Pontiac Power RULES !!! www.wallaceracing.com Winner of Top Class at Pontiac Nationals, 2004 Cordova Winner of Quick 16 At Ames 2004 Pontiac Tripower Nats KRE's MR-1 - 1st 5 second Pontiac block ever! "Every man has a right to his own opinion, but no man has a right to be wrong in his facts." "People demand freedom of speech to make up for the freedom of thought which they avoid." – Socrates |

|

#34

|

|||

|

|||

|

I wasnt suggesting leaving PY to go there...lol. I also wasnt suggesting anyone make it their new home. But in the boosted section there are some topics and discussions I havent seen here yet......and of course vice-versa. If you can avoid the politics that is. Bruce Wilkie is there as well and he may or may not agree....

If you are really fast dairy farmers does that mean the milking gets done faster? Its over before the cows know what hit them? lol Sorry John....I have a warped sense of humor.  |

|

#35

|

||||

|

||||

|

So fast that the cows are milked out.

No more dairy cows now.

__________________

John Wallace - johnta1 Pontiac Power RULES !!! www.wallaceracing.com Winner of Top Class at Pontiac Nationals, 2004 Cordova Winner of Quick 16 At Ames 2004 Pontiac Tripower Nats KRE's MR-1 - 1st 5 second Pontiac block ever! "Every man has a right to his own opinion, but no man has a right to be wrong in his facts." "People demand freedom of speech to make up for the freedom of thought which they avoid." – Socrates |

|

#36

|

|||

|

|||

|

A dairy farmer with no cows.......hmmmm....lol. Today's world is full of surprises. Wouldnt surprise me if in that dairy farm theres a silo undeground, and the SUPER secret guys who use the CIA itself as a cover are busy keeping the world safe

. .Oh, and of course they are Pontiac guys! |

|

#37

|

|||

|

|||

|

So on to answering a few questions about the engine setback...

Here is the car being torn apart to start with the plans I had rolling around in my head, originally just completely seem welding the sub frame and frame connectors that didn't hang down so low. This is how it set as of March 2006:  After tearing the car apart I found my sub frame had a crack in the center cross member, so I seem welded one that I had from another car I bought for the tail panel. Here it is getting the firewall cut out.  To make the alcove for the engine to sit in I bought a wheel barrow and cut out what I needed, I had to add 4.5" to the center to get the heads to tuck in.  For the front motor mount, I had the timing cover milled down 1/4" and the aluminum front plate I made welded to the back. I am using a Lakewood bell housing, so I made my own block protector with ears for the mid mount. Here are pics of the timing cover:   I did all the work in the driveway and worked off a plumb bob and a level. Here are is a pic of the blower being mocked up around the suspension.  In this pic you can see the wheelbarrow alcove where the windshield wiper transmission used to be, you can also tell how far the engine is set back, a full 6" The engine now sits completely behind the center line of the front wheels.   I do not have any pics of inside the car but I will get some. I used a kirkey road race seat and put it where it was most comfortable to me. I feel this really gave me a lot more room because it is mounted as low as I could get it with no adjustments. The dash and steering column stayed in the same place but because the gas pedal had to mount on the back of the alcove I had to move the clutch and brake pedals back 2" to get the pedal relationship right. I obviously haven't driven the car yet but even strapped in the harness I can still reach everything reasonably well. The driving position is comfortable enough but it is definitely all business. I also had to notch out a place in the floor board where your heels fall because of the way it slopes up; moving the pedals back put your heels right on the slope. |

|

#38

|

|||

|

|||

|

Aron you werent on when John left. I understand why he aint going back. I was banned for awhile. You havent been a victim yet. Agree the Turbo Forum is good guys there. Only reason I go there.

Spink that is alot of work. Great job!!! That set back will help traction. You may want an access panel for the distributor though.(Hint... find an old glove box and its surrounding metal.) Advise... find a car project for your lady. If she dont want to be involved with cars she may not be the right one for you. There are ladies out there honestly interested in this stuff. My daughters are spoken for but often have their girlfriends meet up with us at races or car shows. One of my daughters friends used to drive 300mph Jet cars for Hannah(Queen of Spades) and now in alcohol dragsters(and married). (Her mom and my wife grew up together) My wife when we first dated told me not to get any ideas of making her car mine. "You'll be gone before that happens" is what she said. I knew then I had to marry her. Dont let your little head advise the big head  You'd probably enjoy some of the RatRod work my partner and I do. We like S10 and Blazer frames ourselves.(Blazer much stronger) And nice final results. Strong, functional, safe, cost effective! |

|

#39

|

|||

|

|||

|

Yeah, these forums can be nasty at times Bruce....I follow what you are saying. But I agree, the turbo guys are good, and there are some others too.

You have a lot of work into that car spink....glad to see it coming together again. Decent girlfriends at least like riding in the cars......if she doesnt like at least that then Bruce is right.....lol |

|

#40

|

||||

|

||||

|

Nice project Spink, I like that you make the bits yourself from nothing(like the wheelbarrow mod!) and do your own work,rather than just throwing wads of cash at it.

Girlfriends who like cars?  My last four long termers all pretended to like cars at the start of the relationship,but after a couple of years the same old sh*t starts, you know,'Do you HAVE to go to the racing AGAIN this weekend?'. 'My mothers coming over/I want to go shopping/there's some diy to do around the house',etc etc (delete as appropriate) My last four long termers all pretended to like cars at the start of the relationship,but after a couple of years the same old sh*t starts, you know,'Do you HAVE to go to the racing AGAIN this weekend?'. 'My mothers coming over/I want to go shopping/there's some diy to do around the house',etc etc (delete as appropriate)

|

| Reply |

|

|