| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#1

|

||||

|

||||

|

I have a set of Comp Engineering bolt in connectors on my 78 T/A with polygraphite bushings,well im gonna take them out tomorrow cause I can't handle the squeaking.It's downright embarrasing.I am gonna go the weld in route,can anyone recommend which ones are good? which ones to stay away from? Ease of installation?

Thanks

__________________

Brakes? Who needs brakes,they'll just slow you down!! |

|

#2

|

|||

|

|||

|

Polygraphite body bushings? They shouldn't squeek, are they polygraphite or polyurethane?

I would just weld in the comp engineering sfc's...Otherwise the Alston sfc's are good. |

|

#3

|

||||

|

||||

|

No,they're polygraphite.Bought them from P.S.T.

__________________

Brakes? Who needs brakes,they'll just slow you down!! |

|

#4

|

||||

|

||||

|

I have the same CE connectors. They rub the body right in the middle. I put a little wheel bearing grease between the body and the connector and the squeak went away.

Are yours squeaking on the ends?

__________________

Nothing is impossible if you break it down into possibilities. It's all a matter of "Want to". |

|

#5

|

||||

|

||||

|

Quote:

Thanks!

__________________

Brakes? Who needs brakes,they'll just slow you down!! |

|

#6

|

||||

|

||||

|

If you weld in subframe connectors while using rubber or poly body bushings the welds will eventually crack. Bolt them in when using rubber or poly bushings. Install solid body bushings if you want to weld them.

I've got tubular subframe connectors from Pro-Touring F-body installed on my 76, along with just about everything else Dave sells, LOL! I welded them in and used solid body mounts. Before the install, if I put my car on a lift the body would flex to the point of not being able to open or close the doors. After the install, that is no longer the case. I'm amazed at how much more rigid the car is now, without ANY of the harshness in the ride that so many people incorrectly state will happen with solid bushings. What I did notice is that I can now "feel" the drive train in the seat of my pants, not the disconnected feeling I used to have with the stock, rubber bushings. Here are some pics of my car with the connectors installed. You can barely see them under the car. They are made from thick-walled, DOM tubing (drawn over mandrel). They are stronger, lower profile, fit better and perform better than the "boxed" style that bolt under the rear spring perches. It's my belief that the only connectors that are better than these are the type that are cut into, and welded to the floor pan, which require major modification and fabrication.

__________________

John  "There are no stupid questions, but there are a LOT of inquisitive idiots!" |

|

#7

|

||||

|

||||

|

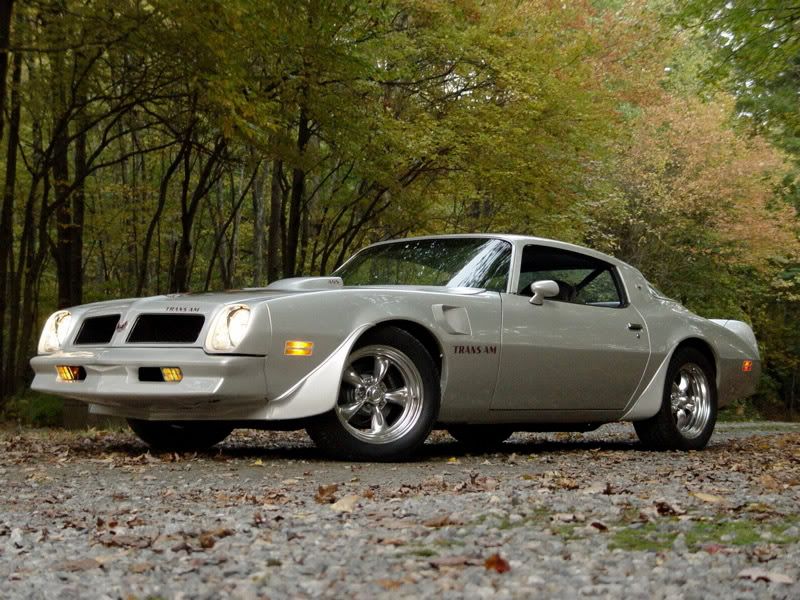

Here's a pic, for comparison, of my car before all of the suspension and chassis mods. You can clearly see my old, boxed Competition Engineering connectors hanging from under the car. These were bolted in and they squeaked too.

__________________

John  "There are no stupid questions, but there are a LOT of inquisitive idiots!" |

|

#8

|

|||

|

|||

|

Quote:

|

|

#9

|

||||

|

||||

|

Quote:

__________________

Brakes? Who needs brakes,they'll just slow you down!! |

|

#10

|

||||

|

||||

|

Mine (pictured above) are welded. bobzdar was just commenting that he has the same connectors, but he has his bolted in with his poly bushings. As I said, if you want to weld connectors in you need to use solid bushings. Poly bushings are fine if you want to bolt them in. I highly recommend going with the solid bushings and welding these tubular connectors in. You won't believe the difference it makes.

__________________

John  "There are no stupid questions, but there are a LOT of inquisitive idiots!" |

|

#11

|

||||

|

||||

|

from the horses mouth

our frame connectors can be welded OR bolted in and come with the hardware to bolt in, don't be confused ours are a complete different design that allows the choice of bolt in or weld in. our frame connectors can be welded OR bolted in and come with the hardware to bolt in, don't be confused ours are a complete different design that allows the choice of bolt in or weld in.

__________________

www.pro-touringf-body.com |

|

#12

|

||||

|

||||

|

Quote:

Thanks, Dean

__________________

Brakes? Who needs brakes,they'll just slow you down!! |

|

#13

|

||||

|

||||

|

Check out this pic again. This is where the connector mounts to the rear frame rail, not just bolted under the rear spring perch. You can see that we filled in the bolt holes with weld and then welded the entire perimeter.

I can't tell you for sure whether or not they will squeak when bolted in, but I suspect not. Bolting them in while using poly bushings is a good alternative until you are ready to swap to solid bushings and weld them in.

__________________

John  "There are no stupid questions, but there are a LOT of inquisitive idiots!" |

|

#14

|

||||

|

||||

|

I'm running a set of the lowering solid aluminum bushings that used to be available from Herb Adams VSE. They aren't harsh at all. I'll be adding SFC's before the silver bird goes back on the road. I've heard that a lot of people will weld the back of the connector in and bolt the front so you can remove the subframe if necessary.

The ProTouring connectors are looking good to me. Stewart

__________________

1976 TA, nose converted to 1970 style, 406, ported #13 Heads, '70 iron intake without crossovers, Q-Jet - Cliff style, RARE OS manifolds, Pypes duals w/crossflow, UD 230/238 custom HR 4/7 swap cam with solid roller lifters  , Hydro-Boost 4-wheel discs, 4 Speed, 3.23 posi. , Hydro-Boost 4-wheel discs, 4 Speed, 3.23 posi.“Nothing in life is so exhilarating as to be shot at without result.” - Winston Churchill |

|

#15

|

||||

|

||||

|

well,I got a buddy to bounce the front end while I got under to trace my squeak.It's the damn Polygraphite lower control arm bushing!! Yes im sure they're polygraphite.I can only guess I did'nt fully grease one with the supplied grease before I put it in.

aside from taking the whole damn thing apart,and if Im going that route I'll just put rubber OEM bushings in,anybody have any suggestions? I soaked it with PB Blaster.Didn't work. I soaked it with white spray can lithium grease. Didn't work.I loosened the bolt prior to this to get the most penetration.WTF? I can't drive this car! I sound like a flock of f**in birds driving down the street!

__________________

Brakes? Who needs brakes,they'll just slow you down!! |

|

#16

|

||||

|

||||

|

Forget the rubber, use delrin style bushings. GW and Detroit Speed Engineering offer ones that fit in your stock lower control arms. They are greasable, very stable and ultra-low friction. Gives a smoother ride than rubber or poly, while at the same time improving the handling because they don't deform under load.

__________________

"The Mustang's front end is problematic... get yourself a Firebird." - Red Forman |

|

#17

|

||||

|

||||

|

Quote:

Go back to good hi-density rubber bushings or as amcmike said get the GW Delalum or other delrin bushings. They are expensive but they are the best you can get and they won't squeak or deflect. MTC, Stewart

__________________

1976 TA, nose converted to 1970 style, 406, ported #13 Heads, '70 iron intake without crossovers, Q-Jet - Cliff style, RARE OS manifolds, Pypes duals w/crossflow, UD 230/238 custom HR 4/7 swap cam with solid roller lifters  , Hydro-Boost 4-wheel discs, 4 Speed, 3.23 posi. , Hydro-Boost 4-wheel discs, 4 Speed, 3.23 posi.“Nothing in life is so exhilarating as to be shot at without result.” - Winston Churchill |

|

#18

|

||||

|

||||

|

I've been telling people for YEARS about the Polygraphite BS, again unless the graphite could have a 100% contact with the rotating sleeve it will touch Poly.... you know the rest of the story.

__________________

www.pro-touringf-body.com |

|

#19

|

||||

|

||||

|

Quote:

Thanks everyone for your input.

__________________

Brakes? Who needs brakes,they'll just slow you down!! |

|

#20

|

||||

|

||||

|

I used the Alston tubular connectors (bolted in) with the poly G frame bushings on my X-body ventura's,no squeaks/noises what-so-ever.

Was real tight on space when the Cal-Tracs were on the car though,but plenty of room with the SSM bars. I personally never use poly or poly G bushings on control arms (front or rear/upper or lower). Much better options available for those pieces.

|

| Reply |

|

|